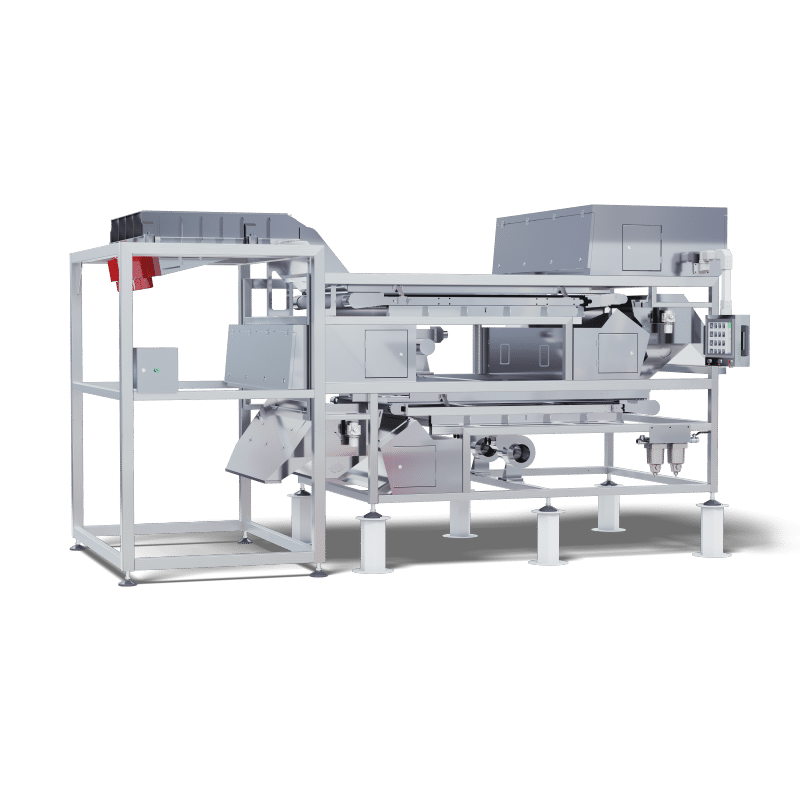

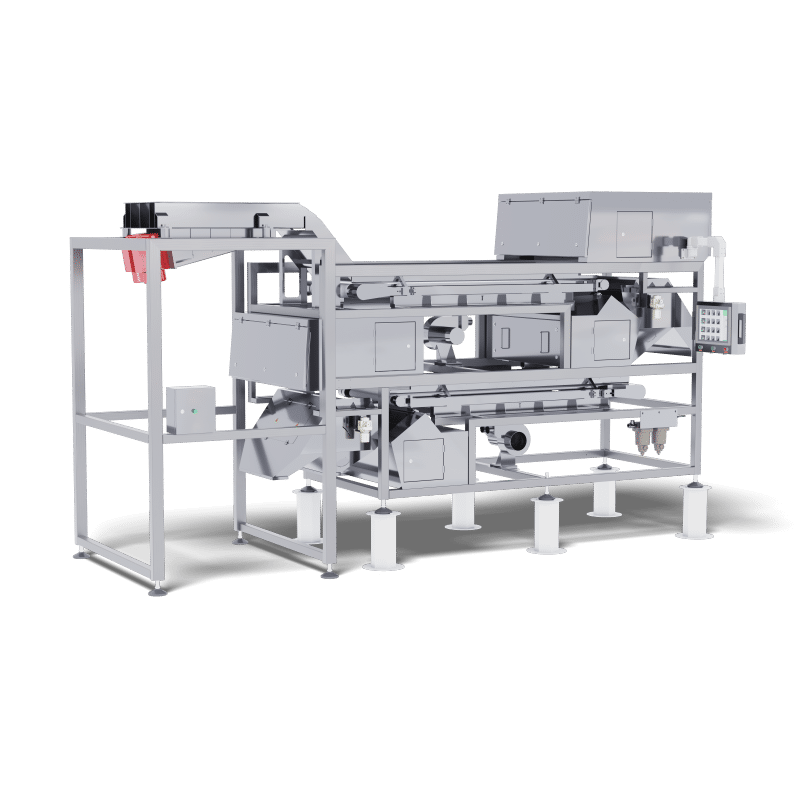

Umatshini wokuSombulula uMbala weRayisi onemisebenzi emininzi

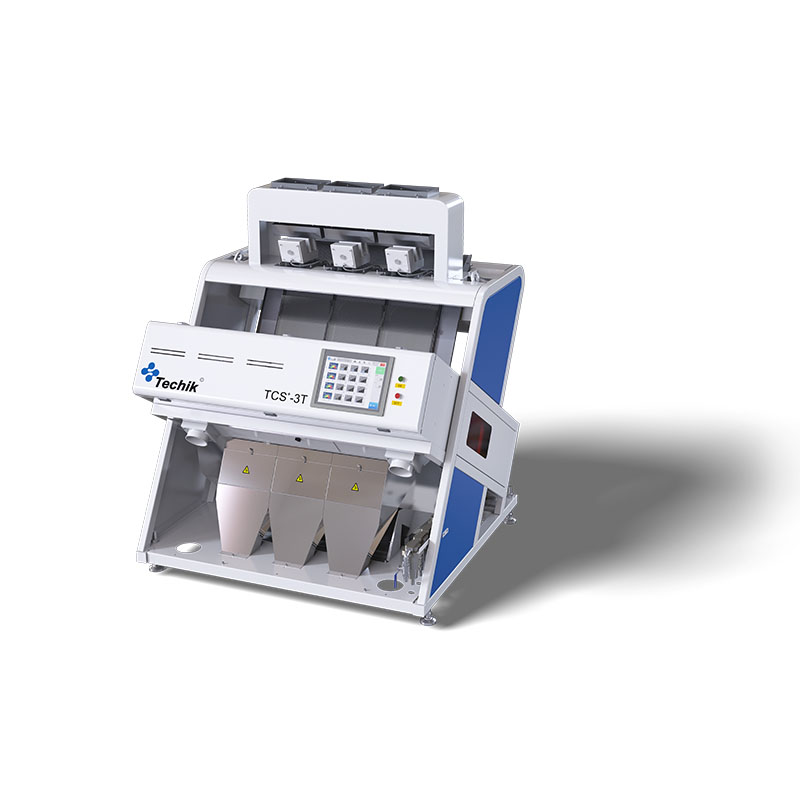

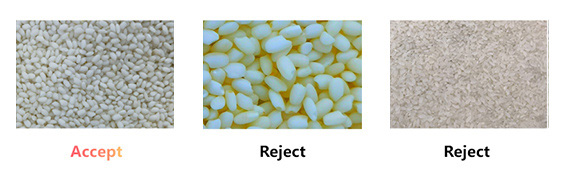

Umatshini wokukhetha umbala werayisi osebenzayo weTechik usetyenziswa ngokubanzi ukuhlenga-hlengisa kunye nokuhlelwa kweerayisi ezahlukeneyo.Ukuhlela irayisi ene-chalky, i-discolor ngaxeshanye kunye nokuhlelwa kwerayisi etshikisiweyo, umthubi, umthubi kunye nokuhlelwa kwerayisi eyaphukileyo kunokuqhutywa ngumatshini wokuhlela umbala werayisi weTechik.Ukongeza, umatshini wokukhetha umbala werayisi osebenzayo unokusetyenziswa kumashishini emveliso yezolimo njengeenkozo, ioats, iimbotyi, iindongomane, imifuno, iziqhamo kunye nokunye.

Ukungcola okuqhelekileyo okuqhelekileyo kunokulungiswa, umzekelo: iglasi, iplastiki, i-ceramic, intambo yentambo, isinyithi, inambuzane, ilitye, inkunkuma yempuku, i-desiccant, intambo, i-flake, i-heterogeneous grain, ilitye lembewu, i-straw, i-corn hull, imbewu yengca, etyumkileyo. iibhakethi, i-paddy, njl.

Umsebenzi wokuhlela weTechik umatshini wokukhetha umbala werayisi osebenzayo.

1. I-INTERFACE ESEBENZAYO YOBUHLOBO

Isoftware yokusebenza kwerayisi ephuhlileyo.

Cwangcisa izikimu ezininzi, khetha ezona zilungileyo oza kuzisebenzisa kwangoko.

Isikhokelo sesiqalo esimiselweyo, i-interface ilula kwaye kulula ukuyiqonda.

Ukusebenzisana komntu nekhompyuter kulula kwaye kuyasebenza.

2. I-ALGORITHM YOBUCHULE

Akukho ungenelelo lwezandla, ukuzifundela nzulu.

Ukuqondwa okukrelekrele kweeyantlukwano ezichuliweyo.

Ukuzaliseka ngokukhawuleza kwendlela yokusebenza elula.

| Inombolo yomjelo | Amandla Aphelele | I-Voltage | Uxinzelelo loMoya | Ukusetyenziswa koMoya | Ubungakanani (L*D*H)(mm) | Ubunzima | |

| 3×63 | 2.0 kW | 180-240V 50HZ | 0.6-0.8MPa | ≤2.0 m³/mz | 1680x1600x2020 | 750kg | |

| 4×63 | 2.5 kW | ≤2.4 m³/mz | 1990x1600x2020 | 900 kg | |||

| 5×63 | 3.0 kW | ≤2.8 m³/mz | 2230x1600x2020 | 1200 kg | |||

| 6 × 63 | 3.4 kW | ≤3.2 m³/mz | 2610x1600x2020 | 1400k g | |||

| 7×63 | 3.8 kW | ≤3.5 m³/ngomzuzu | 2970x1600x2040 | 1600 kg | |||

| 8x63 | 4.2 kW | ≤4.0m3/min | 3280x1600x2040 | 1800 kg | |||

| 10 × 63 | 4.8 kW | ≤4.8 m³/mz | 3590x1600x2040 | 2200 kg | |||

| 12 × 63 | 5.3 kW | ≤5.4 m³/ngomzuzu | 4290x1600x2040 | 2600 kg | |||

Phawula:

1. Le parameter ithatha iJaponica Rice njengomzekelo (umxholo wokungcola ngu-2%), kwaye izikhombisi zeparamitha ezingentla zingahluka ngenxa yezinto ezahlukeneyo kunye nomxholo wokungcola.

2. Ukuba imveliso ihlaziywa ngaphandle kwesaziso, umatshini wangempela uya kuphumelela.